BOILER RETROFITTING & UPGRADING

SCOPE OF SUPPLY

We provide a complete Retrofit UPGRADE of your existing burner and boiler system using LAMTEC GERMANY combustion control technology with scope that includes:KEY BENEFITS

NO Burner Replacement Required

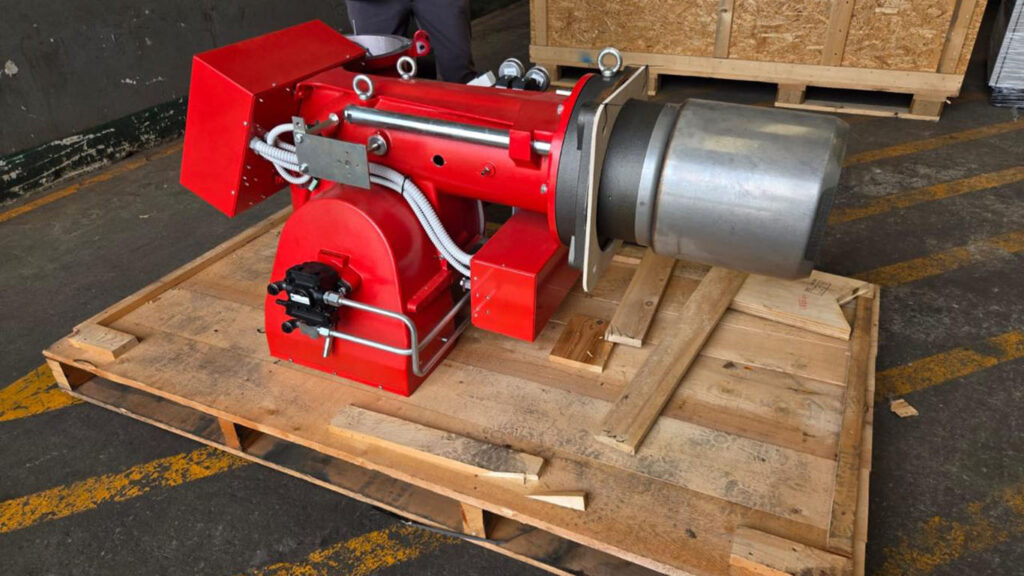

Burner replacement

We supply various burners from reputable brands to meet standards and satisfaction.

Control panel upgrades (automation/digitalization)

Lamtec approach to automation and digitalization as a transformation from mechanical control to intelligent, data-driven combustion management. Our systems act as the “brain” of the boiler, replacing manual adjustments with automated, real-time optimization.

- Burner Management Systems (BMS): Platforms like the CMS (Combustion Management System) and ETAMATIC centralize control by integrating flame monitoring, fuel/air ratio control, and leakage testing into a single digital unit.

- Electronic Fuel/Air Ratio Control: Digital actuators replace mechanical linkages, allowing for precise, repeatable positioning of valves and dampers. This eliminates “slop” or mechanical wear that leads to efficiency drift over time.

- Integrated Soft-PLC: Modern Lamtec systems include an integrated CODESYS Soft-PLC, enabling custom automation sequences for complex, non-fail-safe plant functions directly within the combustion manager.

- Fieldbus Integration: Lamtec devices support standard industrial communication protocols (e.g., Modbus TCP, PROFIBUS, PROFINET), allowing seamless data exchange with higher-level SCADA, DCS, or Building Management Systems (BMS).

- Remote Diagnostics & Maintenance: Digital connectivity enables remote access for monitoring system health, managing alerts, and performing troubleshooting without requiring an on-site technician.

- Visualization: Advanced HMIs like the GUI607 provide high-resolution, touchscreen interfaces for real-time process visualization and data logging.

- CO/O2 Trim Control: This automated “closed-loop” system uses sensors to continuously analyze flue gas and automatically adjust the burner to maintain the “efficiency edge,” compensating for changes in air pressure, humidity, or fuel quality without human intervention.

- Adaptive Control Algorithms: The systems dynamically adjust combustion parameters based on real-time sensor data, ensuring the boiler remains at peak performance regardless of load fluctuations.

- Internet Security: Recognizing the risks of digitalization, Lamtec integrates security features such as data encryption and intrusion protection to safeguard connected boiler systems from external threats.

Energy efficiency retrofits

We emphasize our role as a global leader in high-precision combustion management. Instead of manufacturing boilers, Lamtec provides the sensors and controllers that optimize the burning process to achieve maximum thermal output with minimum fuel.

Our Core Efficiency Technologies

Lamtec systems like the BurnerTronic BT300 use zirconia-based sensors (e.g., LT3-F) to measure exhaust gas. By detecting unburned components (CO/H2), the controller can operate the burner at the “emission edge”—the precise point of maximum efficiency—regardless of changes in air humidity or temperature.

Unlike mechanical linkages that slip over time, Lamtec’s ETAMATIC and CMS systems use electronic actuators for exact positioning, ensuring the fuel-to-air ratio is perfectly matched at every firing rate.

- Integrated control of combustion air fans reduces electrical energy consumption by matching fan speed to the required load, rather than running at full speed and throttling air.

Emission control system implementation (NOx/CO2 compliance)

-

Lower emissions (CO, COe, NOx) for environmental and regulatory compliance.

-

Improved combustion efficiency → less fuel wasted, better heat output.

-

Real-time monitoring and adaptive control → quick response to process changes.

-

Better data for reporting → useful for environmental compliance documentation.