VISIOCONTROL VC1000

Complete System for Burner and Boiler Control

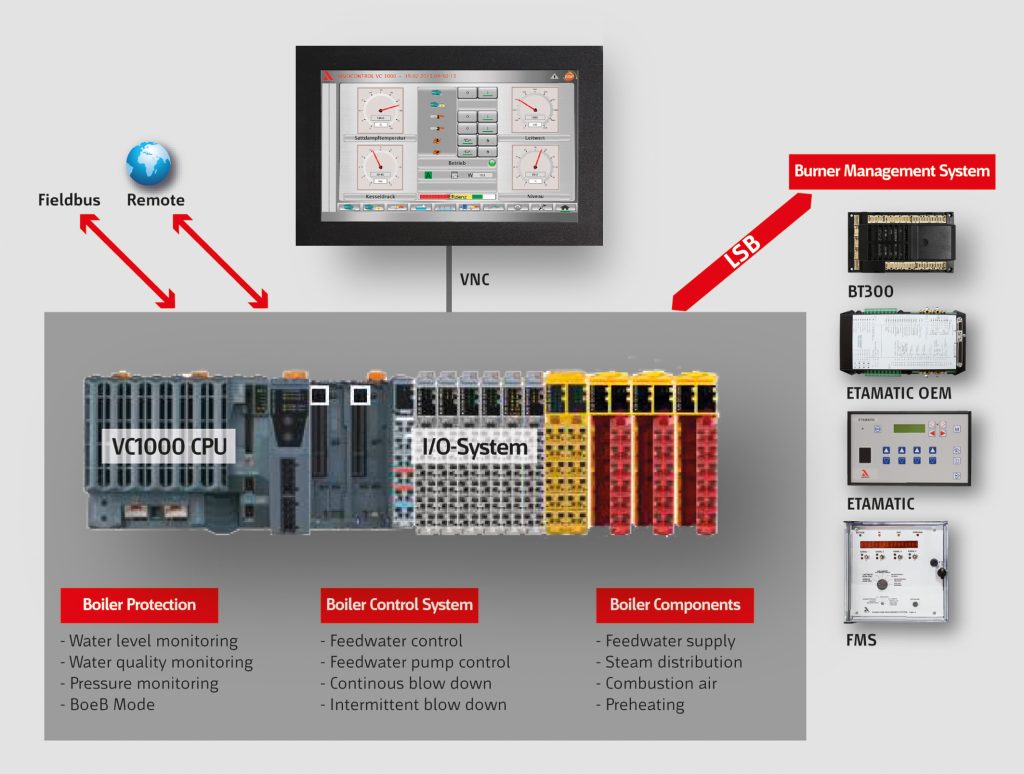

VISIOCONTROL VC1000 is a highly integrated system for the operation and control of a boiler plant.

The main components include the following:

- Burner control system

- Boiler control system

- Boiler protection

- Boiler components

| Display | |

|---|---|

| Size: | 12-24 inch (standard 12 inch) |

| Type: | TFT colour, multitouch |

| Touch Screen: | Projected Capacitive Touch (PCT) |

| Protection class: | IP65 frontal IP20 back (only available with mounted link module or system unit) |

| System Unit Panel PC 2100 | |

|---|---|

| Processor: | Intel Atom E3826 |

| Frequency: | 1460 MHz |

| Memory size: | 2 GByte |

| USB: | 2 (1x USB 3.0 and 1x USB 2.0) |

| Power supply: | 24 VDC ± 25 % |

| Ambient temperature operation: | -20 °C … +40 °C |

| Ambient temperature transport and storage: | -20 °C … +60 °C |

| Dimensions (WxHxD): | 190 x 115 x 29.7 mm |

| Weight: | 577 g |

All modules are networked using LAMTEC SYSTEM BUS.

Any LAMTEC burner control device can be used for the burner control module.

For this purpose, LAMTEC provides the following burner control devices:

- ETAMATIC

- ETAMATIC OEM

- Burner Control FA1

- FMS

- BT300

In comparison with a conventional PLC control device, VISIOCONTROL VC1000 has proven itself to be extremely easy to configure and handle. All burner-specific data is read from the burner control device and displayed to the user through graphical as well as text visualisation.

The commissioning engineer can compile the menu-driven boiler plant including auxiliary units as required. The commissioning engineer requires no PLC programming knowledge for this purpose. The portfolio of VISIOCONTROL VC1000 contains pre-assembled controllers, for output and access level, which can be changed easily without the operator having to switch to the programming level of the system.

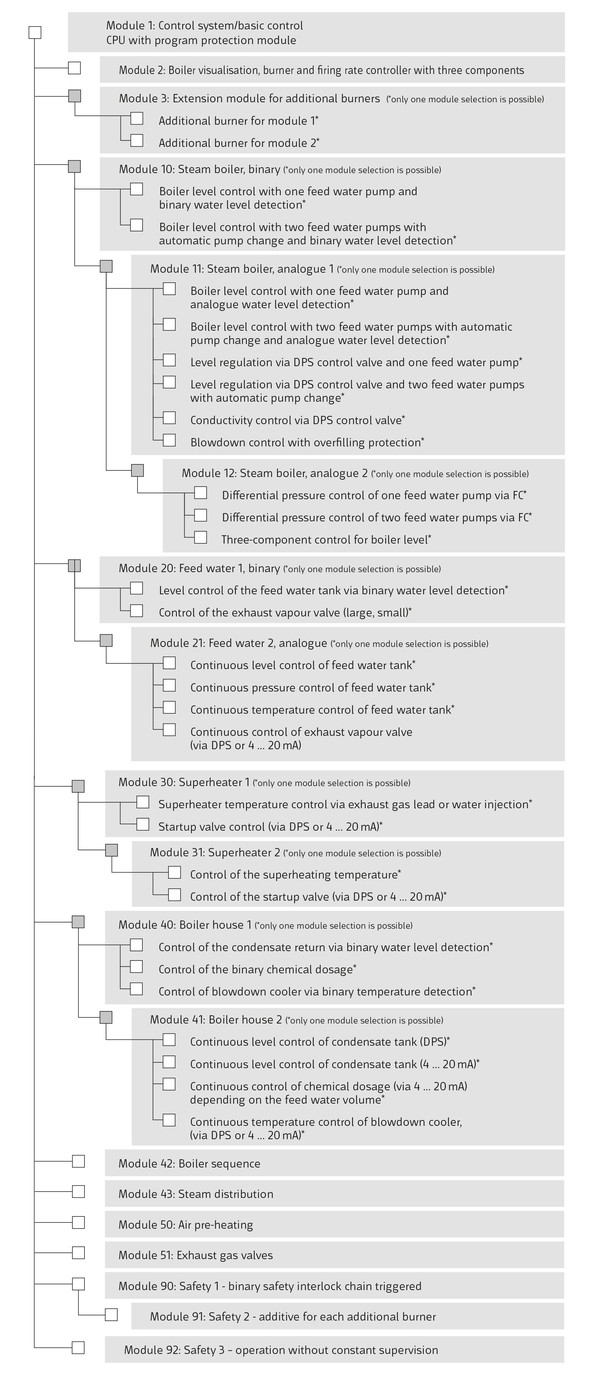

VC1000 is a modular constructed system.

Most boiler applications can be realised by combining the different modules.

System configuration: