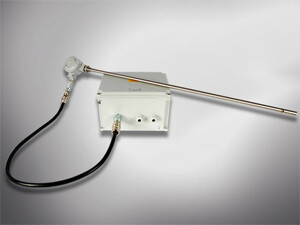

High - End HEI600

- Ignites Gaseous and Liquid Fuels in Burners of ANY Capacity up to heavy oil grade 6

- Compact Design: Control Unit and Ignition Lance are one Unit

- 100% waterproof

- In Conjunction with NFPA 8501/8502 Class 3 Special (Electrical Igniter)

- Available for Hazardous Areas

- Good spark at long distance because of the long lance

Technical Data High-End HEI600

| Characteristics | HEI600 |

| Housing | Wall mounting steel housing |

| Protection Class | IP65/66 |

| Colour | Light grey |

| Spark Frequency | 26 sparks / second |

| Input Power | 724 W ( at 26 sparks / s) |

| Energy | 10 joule (each spark +/- 10%) |

| Power Supply | 115 / 230 VAC 50 Hz (60 Hz on request) |

| Operating Temperature and Humidity | -40 °C … +60 °C non-condensing |

| Duty Cycler 33% | 20 sec ON – 40 sec OFF max 3 times |

Technical Data Ignition Lance

| Characteristics | Ignition Lance |

| Housing Dimensions | 103 x 103 x 76,5 mm |

| Max. Length | 3 m |

| Outer Diameter | 16 mm |

| Temperature of the ignition tip | Standard: 720°C / Special version: 1.000°C |

| Length of connecting cable | According to customer requirements.Up to 50 m possible |

| Connection | 2-wire |

Criteria of using the retraction device:

- Ignition lance is permanently exposed above 600°C

- The ignition tip is exposed at permanent temperature of above 720°C (standard ignition tip)

- The ignition tip is exposed at permanent temperature of above 1000°C (special ignition tip)

- High Pollution in the process

The high-energy igniter works on the principle of storing an electrical charge in a capacitor and discharging it via an ignition tip to produce electrical sparks with sufficient energy to ignite oil particles or gas.

When the high-energy system is supplied with power by connecting it to the power supply, the high-energy control system regulates the necessary power to the primary side of the transformer.

This power limitation in relation to the output energy serves to prevent the high energy igniter from overheating. An overheating protection circuit is additionally provided to prevent damage to the unit in case of very intensive use. By switching on, the primary winding of the transformer is supplied with electrical energy, which induces a high voltage at the secondary winding. This high voltage is rectified and charges a capacitor.

When the voltage of the capacitor reaches the threshold voltage of the spark gap, the gap is ionised. The discharge current flows from the capacitor via the high-energy cable to the spark gap.

By releasing the energy as a spark at the spark tip, the storage capacitor is completely discharged.